Description

PRODUCT PARAMETERS

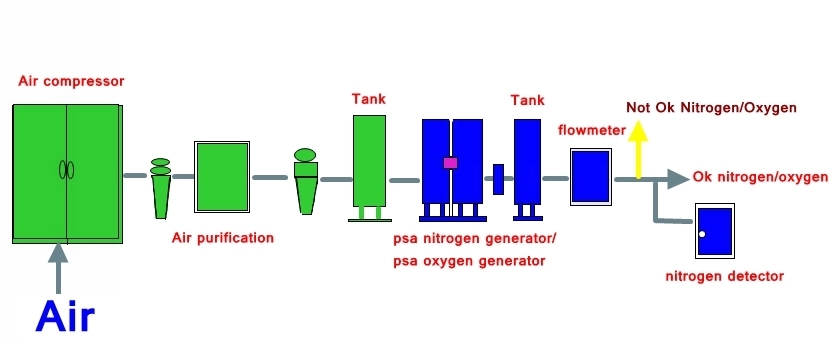

WORKING PRINCIPLE

PSA ( Pressure Swing Adsorption) Technology a revolution in Non Cryogenic Air Separation and Oxygen Generation Technology.

The pressure swing adsorption oxygen generator uses clean compressed air as raw material, uses high-quality zeolite molecular sieve as adsorbent, and produces oxygen from the air under a certain pressure. The purified and dried compressed air is subjected to pressure adsorption and decompression desorption in the adsorber. Due to the aerodynamic effect, the diffusion rate of nitrogen in the pores of zeolite molecular sieve is much higher than that of oxygen, nitrogen is preferentially adsorbed by zeolite molecular sieve, and oxygen is enriched in the gas phase to form finished oxygen. Then, after decompressing to normal pressure, the adsorbent desorbs the nitrogen and other impurities adsorbed to realize regeneration. Generally, two adsorption towers are set up in the system, one tower absorbs oxygen, the other tower desorbs and regenerates, and the opening and closing of the pneumatic valve is controlled by the PLC program controller, so that the two towers circulate alternately, so as to obtain oxygen with higher purity (93 %±3%).

● The start-up speed is fast, and qualified oxygen can be provided within 15-30 minutes;

● The equipment runs fully automatically, and the whole process can be unattended;

● Efficient molecular sieve packing, tighter, firmer and longer service life;

● Stable and adjustable pressure, purity and flow to meet the different needs of customers;

● Reasonable structure, safe and stable, low energy consumption;

PRODUCT DESCRIPTION |

|

APPLICATION AREAS:

Large-scale factories, aquaculture oxygen production, oxygenation, dissolved oxygen, supporting the use of large ozone machines, for the disinfection, sterilization, algae removal of breeding ponds.

Can also be used for:

(1) Electric furnace steelmaking: decarburization, oxygen combustion-supported heating, foam slag melting, metallurgical control and subsequent heating.

(2) Wastewater treatment: oxygen-enriched aeration of activated sludge, pool oxygenation and ozone sterilization.

(3) Field cutting construction: Oxygen-enriched for field steel pipe and steel plate cutting, mobile or small oxygen generators can meet the requirements.

(4) Sewage treatment and non-ferrous metal smelting: Oxygen enrichment is required for smelting steel, zinc, nickel, lead, etc. The PSA method is gradually replacing the cryogenic method.

(5) Glass melting: Oxygen supports combustion and melting, cutting, increasing glass output and prolonging furnace life.

(6) Pulp bleaching and papermaking: chlorine bleaching is converted into oxygen-enriched bleaching, providing cheap oxygen.

(7) Ore processing: used in gold and other production processes, it can improve the extraction rate of precious metals.

(8) Fermentation: Fudai replaces air to supply oxygen for aerobic fermentation, which can greatly improve the efficiency

(9) Drinking water: provide oxygen to the ozone generator for oxygen sterilization.

(10) Oxygen for petrochemical and chemical industry: Oxygen-enriched oxygen is used instead of air for oxidation reaction in the process of petroleum and chemical industry, which can improve the reaction speed and the output of chemical products.

CERTIFICATIONS

PACKAGING & SHIPPING

FAQ

Yes,we are the professioanl manufacturing factory of PSA Oxyen Plant products; We have been focusing PSA Oxyen Plant equipment for more than 10 years, we have over 100 employees and over 50,000 square meters workshops.

Quality is priority. We always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment.

TT or L/C at sight

If you have another question, Please feel free to Contact us